In modern agriculture, lighting has evolved far beyond basic illumination — it is now a crucial tool for maximizing crop performance. As growers aim for higher yields, improved quality, and more sustainable operations, traditional fixed-spectrum lighting systems such as High-Pressure Sodium (HPS) are showing their limitations. Their static red-orange spectrum, high heat output, and lack of flexibility make them less suitable for today’s precision-driven farming practices.

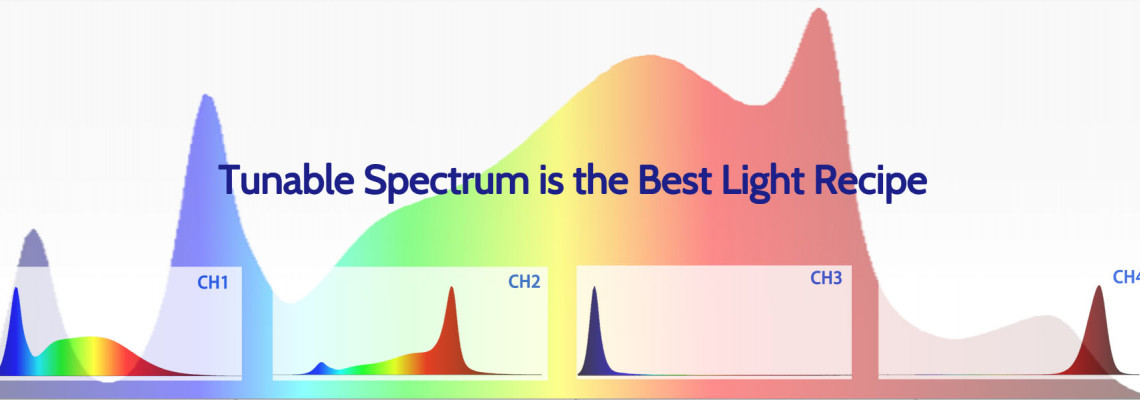

This is where tunable LED spectra are transforming the industry. Unlike HPS, tunable LEDs allow growers to precisely adjust light wavelengths and intensity based on each stage of plant growth. Whether boosting blue light for compact vegetative growth or increasing red and far-red for enhanced flowering, dynamic LEDs provide targeted control that fixed lighting simply can’t achieve.

These systems also support data-driven farming by integrating with smart controls, sensors, and automation technologies. The result is optimized energy use, consistent crop morphology, and improved yields — all while reducing heat, operational costs, and environmental impact.

In this blog, we explore how tunable LEDs function, why static lighting is becoming outdated, and how growers are seeing remarkable improvements in both productivity and product quality by adopting flexible, spectrum-adjustable lighting solutions.

Why Fixed HPS Lighting Is No Longer Enough

For decades, HPS lighting dominated commercial cultivation thanks to its affordability and strong red-orange output that supported flowering. However, fixed HPS systems have significant limitations:

1. Static Spectrum

HPS bulbs deliver a single, unchangeable spectral output heavily skewed toward red and orange wavelengths. While helpful for flowering, this spectrum does little for early vegetative development or specialized crop needs.

2. High Heat Output

HPS lights generate excessive heat, forcing growers to compensate with costly cooling systems. This not only consumes more energy but also restricts how close lights can be mounted to plant canopies, reducing efficiency in multi-tier setups.

3. Shorter Lifespan & More Waste

HPS bulbs degrade quickly, requiring regular replacements. Their components — including glass, metal parts, and in some cases mercury — make disposal and recycling complicated.

4. Limited Control

There is no way to adjust the spectrum or intensity in response to plant stage, environment, or real-time data. The result is wasted energy and suboptimal crop performance.

These limitations have created a clear need for a smarter, more flexible lighting solution — and tunable LEDs provide exactly that.

The Rise of Tunable LED Spectra in Modern Farming

Tunable LEDs are designed to give growers full control over the light plants receive. Using advanced diodes, growers can adjust the spectrum, intensity, and even photoperiod at any time. This flexibility is revolutionizing how commercial farms operate.

Here’s how tunable LEDs outperform fixed-spectrum lighting:

1. Tailored Light Recipes for Every Growth Stage

Plants require different wavelengths during different phases of development:

Seedlings: Blue and green light support compact, strong early growth.

Vegetative: A balanced blend of blue and red encourages healthy leaf development.

Flowering/Fruiting: Increased red and far-red promotes blooming and fruit formation.

With tunable LED systems, growers simply adjust the spectrum based on plant needs. This optimization leads to:

Faster germination

Stronger stems

Higher flower counts

Improved fruit size and uniformity

This level of precision is impossible with static HPS lighting.

2. Enhanced Crop Quality with Targeted Spectra

Different wavelengths trigger different plant responses. By tuning the spectrum, growers can influence:

• Color

LEDs can boost anthocyanins (for red/purple crops) and chlorophyll production (for leafy greens).

• Flavor & Aroma

Specific light recipes enhance terpenes, flavonoids, and essential oils — critical for herbs, medicinal crops, and specialty plants.

• Nutrient Density

Blue and UV light boosts antioxidant production in microgreens, vegetables, and fruiting crops.

• Texture & Form

Plants grown under tuned spectra tend to be more compact, sturdy, and visually appealing.

In short, tunable LEDs allow growers to grow not just more, but better.

3. Higher Yields Through Precision Light Management

Yield is a key driver for any commercial grower. Tunable LEDs improve yields by:

Ensuring plants receive the right spectrum at every stage

Providing uniform distribution across the canopy

Allowing lights to be placed closer to plants due to low heat

Reducing stress and increasing photosynthetic efficiency

Studies show that tunable LED systems regularly outperform HPS systems in total biomass, flower count, and harvest weight.

4. Adaptive Lighting Responds to Real-Time Conditions

One of the biggest advantages of tunable LEDs is the ability to integrate with smart controls and sensors. Modern LED systems can automatically adjust light output based on:

DLI (Daily Light Integral)

Temperature shifts

CO₂ levels

Plant responses (monitored by AI systems)

Natural light availability

This means lighting becomes dynamic — changing minute-by-minute to deliver exactly what plants need without wasting energy.

5. Reduced Heat, Lower Energy Costs

Heat is one of the biggest limitations of HPS lighting. Tunable LEDs drastically reduce heat output, allowing for:

More efficient multi-tier rack systems

Lower cooling costs

Higher light intensity without stress

Additionally, LEDs consume significantly less electricity than HPS systems while delivering higher-quality light. The combination of lower energy consumption and reduced HVAC loads can save growers 40–60% in operational costs.

6. Longer Life Span & Lower Waste

Tunable LEDs offer exceptional durability:

50,000–100,000 hours of lifespan

Minimal degradation over time

No toxic chemicals like mercury

Easier recycling due to modular components

For growers prioritizing sustainability, LEDs significantly reduce electronic waste compared to constantly replaced HPS bulbs.

7. Spectrum Flexibility Enables Crop Diversification

With tunable LEDs, growers can easily switch between crops without changing hardware. This is especially valuable for:

Vertical farms

Specialty crop growers

R&D facilities

Universities and horticulture labs

Whether growing leafy greens, strawberries, herbs, or medicinal plants, tuning the light recipe is as simple as selecting a preset or customizing a spectrum.

This flexibility allows growers to experiment, diversify their offerings, and respond quickly to market demand.

8. Improved Consistency and Predictable Outcomes

Consistency is crucial for commercial success. Tunable LEDs provide:

Steady spectral output

Uniform PPFD across the canopy

Reduced microclimates

Precise control over plant morphology

This leads to predictable harvest cycles, better planning, and improved profit margins.

Conclusion: The Future Is Flexible

As agriculture becomes more data-driven, sustainable, and quality-focused, static lighting systems like HPS simply cannot keep pace. Tunable LED spectra represent the next evolution in crop lighting — offering unmatched control, efficiency, and performance.

By shifting from fixed to flexible lighting, growers benefit from:

Higher yields

Better crop quality

Lower operating costs

Greater sustainability

More control over plant outcomes

In short, tunable LEDs don’t just illuminate crops — they empower growers to maximize every stage of plant development.

The farms of the future will be built on dynamic, responsive, and intelligent lighting systems. And tunable LEDs are leading the way.

12 Comment(s)

Why visitors still make use of to read news papers when in this technological globe all is existing on web?

Hi! I've been reading your website for a long time now and finally got the bravery to go ahead and give you a shout out from Dallas Tx! Just wanted to tell you keep up the fantastic job!

You've made some decent points there. I checked on the internet to learn more about the issue and found most individuals will go along with your views on this web site.

Way cool! Some very valid points! I appreciate you penning this write-up and also the rest of the site is very good.

thank you for this post, I am a big fan of this website would like to keep updated.

I’m curious to find out what blog platform you are working with? I’m having some small security problems with my latest blog and I’d like to find something more safe. Do you have any recommendations?

187060 746646Intriguing post. Positive that Ill come back here. Good function. 572053

Ahaa, its fastidious discussion about this post at this place at this weblog, I have read all that, so now me also commenting at this place.

I visited several web sites except the audio feature for audio songs current at this site is in fact wonderful.

Ahaa, its nice conversation regarding this post at this place at this web site, I have read all that, so at this time me also commenting here.

I love it when people come together and share thoughts. Great blog, continue the good work!

It's great that you are getting ideas from this piece of writing as well as from our dialogue made here.

Leave a Comment