In controlled environment agriculture (CEA), lighting plays a critical role in shaping crop performance, quality, and profitability. For decades, High-Pressure Sodium (HPS) lamps dominated the industry, offering high-intensity illumination that powered large-scale indoor and greenhouse farming. Their reliability and strong light penetration made them the go-to choice for growers looking to maximize yields, especially during flowering and fruiting stages.

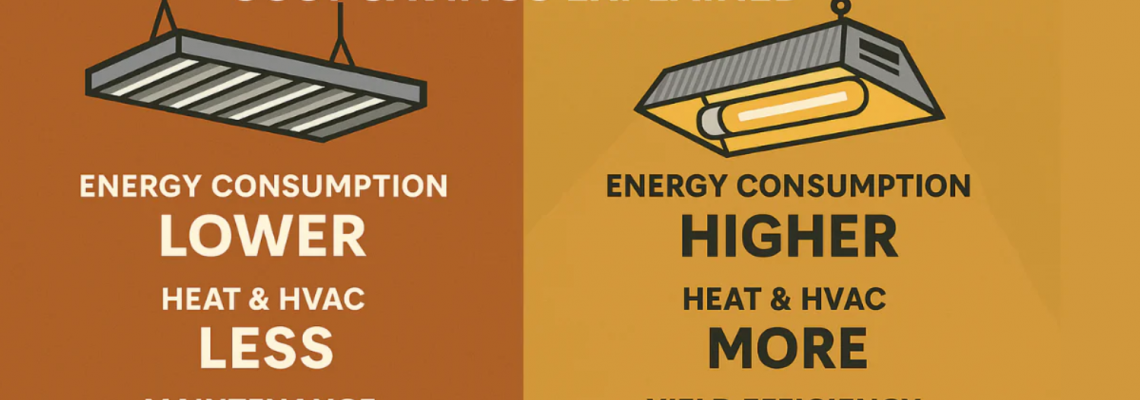

However, farming technologies are evolving rapidly, and Light Emitting Diode (LED) systems are leading this transformation. Unlike HPS lamps, which offer a limited spectrum and generate substantial heat, LEDs provide energy-efficient, customizable lighting solutions that align more closely with plant biology. By delivering precise wavelengths such as blue light for vegetative growth and red light for flowering, LEDs enable growers to fine-tune their crops’ development at every stage.

Beyond spectrum control, LEDs stand out for their longevity, reduced heat output, and lower operational costs, making them not just a tool for cultivation but a long-term investment. While HPS lights remain valuable in certain contexts, the real question for modern agriculture is whether LEDs can surpass them in terms of yield, quality, and sustainability. This article explores the yield debate, comparing performance, economics, and future potential of both lighting systems.

Understanding HPS Lighting

High-pressure sodium lights have been a staple in agriculture for decades. Known for their high lumen output and deep canopy penetration, HPS lamps excel at driving photosynthesis during flowering and fruiting stages. Their intense yellow-orange spectrum favors plant productivity but lacks balance across the full spectrum of light plants naturally receive from the sun.

Strengths of HPS:

Proven track record in commercial farming.

Strong light intensity, ideal for fruiting and flowering.

Lower upfront costs compared to LEDs.

Weaknesses of HPS:

High heat output requires extensive cooling systems.

Limited spectrum control.

Higher electricity consumption.

Shorter lifespan, leading to frequent replacements.

The Rise of LED Lighting in Agriculture

LEDs have revolutionized horticultural lighting by offering versatility, energy efficiency, and spectrum precision. Unlike HPS lamps, LEDs can be engineered to deliver specific wavelengths that align with plant growth needs—blue for vegetative growth, red for flowering, and even far-red and UV for advanced crop development.

Strengths of LEDs:

Up to 70% lower energy consumption than HPS.

Minimal heat production, reducing HVAC costs.

Full-spectrum options that mimic natural sunlight.

Long lifespan—often exceeding 50,000 hours.

Ability to integrate with smart systems for spectrum and intensity control.

Weaknesses of LEDs:

Higher initial investment.

Performance varies depending on fixture quality.

Yield Comparison: LEDs vs. HPS

When it comes to yields, the debate intensifies. Farmers and researchers have run countless trials comparing HPS and LED systems, and while results can vary based on crop type, setup, and environmental conditions, several trends are clear:

Higher Yields in Certain Crops

Studies show that crops like leafy greens, herbs, and strawberries often perform better under LED lighting due to optimized spectrum delivery. For fruiting crops like tomatoes or peppers, LEDs have been shown to match and in many cases surpass HPS yields.

Improved Crop Quality

LEDs don’t just impact quantity; they also influence quality. Spectrum tuning enhances traits like color, flavor, and nutrient density, giving crops added market value. HPS, with its narrow spectrum, cannot deliver the same precision.

More Crop Cycles per Year

Because LEDs emit less heat, growers can place fixtures closer to the plant canopy. This increases light absorption, shortens growth cycles, and enables more harvests annually compared to HPS systems.

Energy and Cost Balance

Even if yields between HPS and LEDs appear similar in some trials, LEDs deliver those results with significantly lower energy use. Over time, the combination of energy savings and reduced cooling needs translates into higher profitability per crop cycle.

Economic Considerations

At first glance, HPS may seem more attractive due to lower upfront costs. However, when calculating the total cost of ownership, including energy, cooling, bulb replacement, and maintenance, LEDs almost always prove more cost-effective in the long run.

For example, a commercial grower switching from HPS to LEDs might see:

40–60% reduction in electricity bills.

Lower HVAC expenses due to less heat generation.

Fewer disruptions from maintenance and bulb changes.

Higher revenue from improved crop quality and faster cycles.

Sustainability and Environmental Impact

Today’s consumers and regulators place heavy emphasis on sustainability. In this regard, LEDs have a clear advantage. Their reduced energy demand directly lowers greenhouse gas emissions, and their mercury-free design makes disposal safer compared to HPS or fluorescent alternatives.

For growers seeking eco-certifications or government incentives, transitioning to LEDs can open doors to financial benefits while strengthening their brand’s green reputation.

The Role of Smart Farming and LEDs

Modern LED systems go beyond lighting they’re agricultural tools. Many integrate with Internet of Things (IoT) platforms and artificial intelligence, allowing farmers to:

Adjust spectrum and intensity in real time.

Automate photoperiods to align with crop stages.

Collect and analyze data to refine growing strategies.

This precision is impossible with HPS lamps, which remain fixed in output and spectrum. In the age of data-driven agriculture, this makes LEDs not just preferable but essential.

Crop-Specific Insights

Leafy Greens & Herbs: LEDs consistently outperform HPS by boosting both biomass and nutrient content.

Fruit-Bearing Crops (Tomatoes, Peppers): Comparable yields, but LEDs provide better fruit uniformity and reduced energy costs.

Cannabis Cultivation: Many growers report higher yields per watt with LEDs, along with enhanced cannabinoid and terpene profiles due to customizable spectrum.

Future Outlook: LEDs Leading the Way

As the industry shifts toward sustainability and efficiency, LEDs are increasingly positioned as the future of horticultural lighting. With costs declining year after year, even small-scale growers are finding it feasible to adopt LED systems. By 2025 and beyond, the advantages of LEDs in yield, energy savings, and quality make them the clear winner in most agricultural settings.

Conclusion

So, can LEDs outperform HPS in crop output? The evidence says yes, especially when considering not just raw yield but also crop quality, cost efficiency, and sustainability. While HPS has served growers well for decades, its limitations in spectrum, heat, and energy use make it less viable for modern farming challenges.

LEDs, with their tunable spectrum, long lifespan, and integration with smart systems, offer growers the tools to maximize yield and profitability in an increasingly competitive agricultural market. For those aiming to future-proof their operations, the shift to LED lighting isn’t just an upgrade; it’s a necessity.

Leave a Comment