For decades, High-Pressure Sodium (HPS) lamps dominated the horticulture lighting industry. Their strong red-orange spectrum made them a go-to solution for flowering crops, delivering high light output at a relatively low upfront cost. But as agriculture continues to evolve with vertical farms, climate-controlled greenhouses, and precision cultivation becoming the new norm—growers are realizing the limitations of relying on a static spectrum.

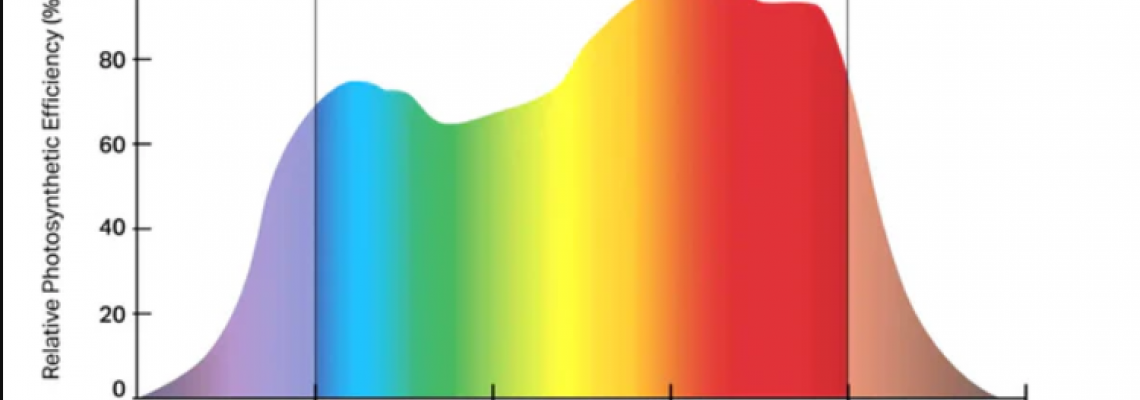

Plants are far more sophisticated than we once thought. They respond to a wide range of wavelengths, each influencing growth, structure, flavor, nutrient density, and flowering behavior. As scientific understanding deepens, growers are increasingly embracing dynamic LED lighting a solution that offers tunable spectra, energy efficiency, and precise control over plant development at every stage.

This blog explores why static HPS lighting is no longer enough and how dynamic LEDs are transforming the future of horticulture.

1. The Limits of Static HPS Red-Orange Lighting

HPS lamps produce a fixed red-orange spectrum (around 570–630 nm) that cannot be adjusted. While this narrow spectrum works reasonably well for flowering, it falls short in meeting the full needs of plant physiology.

Key Limitations of HPS Static Light:

a. Poor Blue Light Output

Plants require blue wavelengths (400–500 nm) for:

Strong root development

Compact structure

Leaf expansion

Overall plant vigor

HPS lacks adequate blue light, often causing plants to stretch or become leggy.

b. No UV or Far-Red Control

UV and far-red wavelengths influence:

Flavor

Color expression

Antioxidant production

Flowering speed

Without these spectra, HPS-grown plants may have lower nutrient density or weaker color formation.

c. Inefficient Energy Use

HPS lamps generate excessive heat, forcing growers to spend more on:

Cooling systems

Ventilation

Airflow management

This added heat also limits multi-layer setups such as vertical farms.

d. One Spectrum for All Stages?

Seedlings, vegetative growth, and flowering all require different spectral balances — something HPS cannot provide. The plant is forced to adapt, often at the cost of quality or yield.

2. Enter Dynamic LEDs: Light That Adapts to the Plant

The agriculture industry is quickly shifting toward LED systems—but not just for efficiency. The real breakthrough lies in dynamic spectrums, also called tunable LED spectra, that can be adjusted to match plant needs in real time.

What Makes Dynamic LEDs Superior?

a. Full-Spectrum Capability

LEDs can produce a wide range of wavelengths:

UV

Blue

Green

Red

Deep red

Far-red

This allows growers to mimic sunlight or create custom recipes for specific crops.

b. Stage-Specific Light Recipes

Plants thrive when given the right spectrum at the right time.

Seedling / Early Veg

Higher blue light

Promotes compact growth

Vegetative Stage

Balanced blue and red

Enhances leaf formation and root strength

Flowering

High red and far-red

Increases bud/fruit density

This dynamic adjustment leads to:

Higher yields

Better crop consistency

Improved quality metrics

c. Enhanced Photomorphogenesis

LEDs enable precise control over plant morphology, influencing:

Leaf size

Stem thickness

Internode spacing

Root development

This level of precision is impossible with static HPS lamps.

3. How Dynamic Spectrum Improves Plant Quality

a. Nutrient Density & Flavor Profiles

UV and blue light stimulate the production of:

Antioxidants

Flavonoids

Essential oils

Pigments

This leads to more flavorful herbs, more colorful leafy greens, and higher-value premium crops.

b. Stronger Structure & Higher Biomass

With the right blue: red balance, plants build thicker stems and stronger roots, improving resilience and transplant success.

c. Faster Growth Cycles

Dynamic LEDs can shorten the vegetative period or accelerate flowering by manipulating far-red and intensity levels.

d. Consistency Across Seasons

Unlike HPS or sunlight, LED output doesn’t fluctuate:

No seasonal variation

No degradation of spectral quality

No temperature-induced changes

This helps commercial growers meet demand reliably year-round.

4. Energy Savings and Cooling Benefits

HPS systems convert as much as 70% of their energy into heat, forcing growers to cool their environment aggressively.

LEDs, by contrast:

Run cooler

Use less electricity

Reduce HVAC loads

Extend equipment life

When used in vertical farms, LEDs enable multi-tier racks placed just inches above plants — something impossible with HPS due to heat.

The cost savings over 3–5 years are often dramatic, making LEDs the clear long-term winner.

5. Smarter Agriculture Through Integration

Dynamic LEDs pair seamlessly with:

AI-driven controls

Light sensors

Climate automation systems

Real-time plant monitoring

Digital light recipes

This integration enables:

Automatic spectrum adjustments

Energy optimization

Data-driven crop planning

HPS systems simply cannot offer this level of intelligence.

6. Real-World Grower Insights

Growers transitioning from HPS to dynamic LEDs often report:

✔ Higher yields

✔ Better-quality produce

✔ Reduced heat issues

✔ Lower energy bills

✔ More control over morphology

✔ Greater consistency across batches

For high-value crops like leafy greens, herbs, strawberries, cannabis, and ornamentals, LED adoption rates continue to rise rapidly.

7. Why HPS Is Becoming Obsolete

HPS lighting is losing ground because:

Its spectrum is fixed and outdated

It consumes more energy

It produces too much heat

It limits scalability

It cannot support multi-layer production

It lacks photobiology precision

It is incompatible with automated smart farms

As agriculture evolves, growers need lighting that evolves with it—dynamic LEDs.

Conclusion: The Future Belongs to Dynamic Lighting

Plants are biological machines driven by light. If the spectrum is static, growth potential is capped. The rise of dynamic LED systems marks a major shift toward intelligent, plant-centered cultivation, replacing outdated red-orange HPS lamps with tools that offer:

2 Comment(s)

I just could not go away your website prior to suggesting that I actually loved the usual information an individual provide in your guests? Is going to be back regularly to check up on new posts

Ahaa, its fastidious conversation on the topic of this piece of writing here at this web site, I have read all that, so at this time me also commenting here.

Leave a Comment