Lighting is at the core of controlled-environment agriculture, driving plant growth, crop quality, and overall yield. While growers often focus on light intensity and spectrum, there’s another factor that plays a critical role in uniform light distribution. Plants don’t just need strong light; they need it to be distributed evenly across the entire canopy. Uneven coverage often creates hotspots and shadows, resulting in inconsistent growth, wasted energy, and reduced productivity.

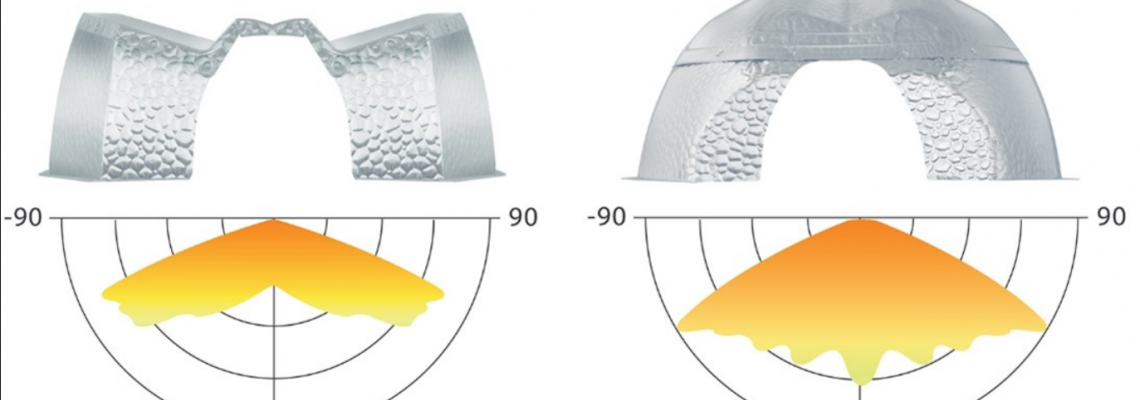

For decades, High-Pressure Sodium (HPS) lighting systems have been the industry standard. These fixtures rely on reflectors to redirect their broad, 360-degree light output down toward crops. While functional, reflectors come with inherent drawbacks. They often create concentrated hotspots beneath the fixture. At the same time, areas farther away remain dim, forcing growers to either accept uneven plant development or increase the number of fixtures, raising energy and maintenance costs.

By contrast, LED grow lights are inherently directional. Instead of scattering light in all directions, LEDs emit targeted beams that can be strategically positioned for even canopy coverage. This precision minimizes waste, reduces shadows, and ensures each plant receives the same amount of usable light. The result is healthier, more uniform crops, greater efficiency, and improved long-term returns for growers.

Why Light Uniformity Matters

Uniform light distribution means that every plant in a growing area receives the same intensity and quality of light. When lighting is uneven, problems arise:

Hotspots: Some plants get too much light, leading to stress or heat damage.

Shadows: Others get too little light, resulting in stunted growth.

Inconsistent yields: Uneven development across the crop canopy reduces overall harvest quality.

Wasted energy: Electricity is consumed, but not all of it translates into usable light for photosynthesis.

For growers, uniform lighting is not just a “nice-to-have.” It’s essential for maximizing return on investment (ROI), ensuring predictability, and maintaining quality across every harvest.

Reflector-Based HPS: A Traditional Approach

High-pressure sodium lamps have long been the standard in greenhouses and indoor farms. Their success stemmed from two main factors: intense light output and affordability. But HPS systems produce light in all directions—360 degrees. To make this usable, reflectors are installed around the bulb to redirect light downward onto the plants.

Limitations of Reflector-Based HPS:

Light Loss

Even with reflectors, a significant amount of light is lost to reflection inefficiencies or scattered beyond the target area.

Hotspots and Shadows

Reflectors concentrate light unevenly, creating intense hotspots directly below the lamp while leaving edges dimmer.

Maintenance

Reflectors degrade over time, accumulating dust or corrosion, further reducing efficiency.

Heat Output

HPS lamps produce large amounts of radiant heat, forcing growers to balance cooling with lighting.

In short, reflector-based HPS systems provide powerful illumination but fall short in creating uniform, energy-efficient coverage.

Directional LEDs: Precision Lighting

LEDs operate on a fundamentally different principle. Instead of emitting light in all directions, LEDs are inherently directional they emit light in a 120° or narrower beam angle. This eliminates the need for reflectors and allows growers to deliver photons directly to the plant canopy.

Advantages of Directional LEDs:

Uniform Distribution

By arranging diodes strategically on fixtures, LEDs provide consistent coverage with fewer hotspots and shadows.

Higher Efficiency

No reflectors means minimal light loss. Nearly all the energy consumed is converted into usable plant light.

Customizable Spectrum

Unlike HPS, which has a fixed spectrum, LEDs can deliver tailored light recipes (blue, red, far-red) precisely and evenly.

Lower Heat Output

LEDs produce less radiant heat, allowing fixtures to be placed closer to plants without risk of scorching.

Longevity

With lifespans often exceeding 50,000 hours, LEDs maintain consistent performance over time, unlike HPS reflectors that degrade.

The Impact on Crop Performance

HPS Challenges in Practice

In HPS-lit greenhouses, plants directly under the fixture may thrive due to high light intensity, but those at the periphery often lag behind. This uneven growth complicates harvesting and reduces overall yield quality.

LED Uniformity Benefits

LEDs, with their directional light, provide even canopy penetration. Every plant, whether in the center or edge of the grow area, gets equal light exposure. This translates into:

Consistent growth patterns

Improved crop quality

Higher total yields

Simplified management and harvesting

Energy Efficiency: Where LEDs Outshine HPS

Uniformity directly ties into energy savings. With HPS, growers often overcompensate by installing more fixtures or increasing wattage to cover darker spots. This raises both electricity costs and cooling expenses.

LEDs, by focusing light exactly where it’s needed, allow growers to achieve the same—or better—results with fewer watts. According to industry studies, switching from HPS to LED can save 30–50% in energy consumption, with added benefits of reduced HVAC loads due to lower heat.

Long-Term ROI: Reflectors vs. Directional Design

When considering costs, many growers focus on upfront fixture price. HPS is undeniably cheaper to purchase than LED. But when factoring in replacement cycles, reflector degradation, energy costs, and crop performance, LEDs often deliver a much higher long-term return on investment (ROI).

HPS ROI Risks: Frequent bulb replacements (10,000–20,000 hours), declining reflector efficiency, higher power bills.

LED ROI Gains: Long lifespan (50,000+ hours), consistent uniformity, energy savings, better crop outcomes.

Sustainability and Environmental Impact

Another key difference lies in environmental responsibility. HPS bulbs contain mercury, requiring special disposal processes and posing ecological hazards. LEDs are mercury-free, aligning with sustainability goals and regulatory trends favoring eco-friendly technology.

Real-World Applications

Greenhouses: Uniform lighting ensures that edge plants perform as well as those in the middle, maximizing use of space.

Vertical Farms: With multiple stacked layers, uniformity is critical to avoid shadows between shelves. LEDs excel here due to their slim, directional design.

Specialty Crops: Herbs, flowers, and cannabis rely heavily on light consistency for premium quality. LEDs give growers a reliable advantage.

The Future of Lighting: Directionality as the Standard

As horticulture embraces automation, IoT, and precision agriculture, directional LEDs are becoming the gold standard. Their ability to integrate with smart systems, deliver consistent light, and reduce waste positions them far ahead of reflector-based HPS in modern farming strategies.

HPS may have served as the backbone of controlled environment agriculture for decades, but the shift toward LEDs isn’t just about efficiency it’s about precision, predictability, and sustainability.

Conclusion

When comparing directional LEDs to reflector-based HPS, the winner is clear. LEDs eliminate the inefficiencies of reflectors, provide superior uniformity, and support long-term energy and sustainability goals. For growers aiming to maximize yield, reduce costs, and future-proof their operations, LEDs aren’t just an upgrade they’re a necessity.

Leave a Comment